Introduction To Sealing Strip

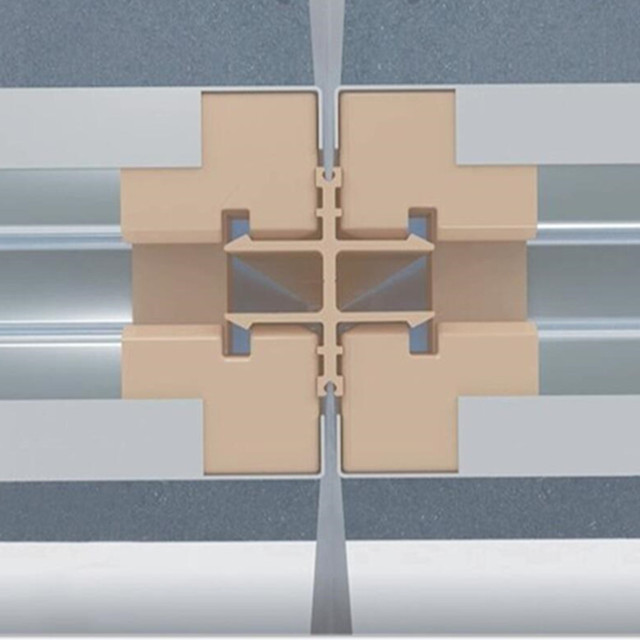

The sealing strip is made of PP+TPE two soft and hard materials through precision mold and professional co-extrusion technology. PP is one of the hard materials with excellent physical and chemical properties. Has a certain impact resistance, strong resistance to bending and deformation.

The sealing strip is made of PP+TPE two soft and hard materials, which are integrated and formed by precision molds and professional co-extrusion technology. PP is one of the hard materials with excellent physical and chemical properties. It has a certain impact resistance, strong resistance to bending and deformation, and can be used in a lower and certain high temperature environment while maintaining good performance. Fire retardant can be achieved according to different use environment requirements.

The chemical stability of PP is very good. In addition to being corroded by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. It has good acid and alkali corrosion resistance, as well as good anti-aging and weather resistance characteristics.

TPE is one of the soft materials. TPE material is a non-toxic and environmentally friendly elastomer material, which is soft to the touch, high strength, high resilience and temperature resistance. It can reach the hygienic environmental protection standard.

Good aging resistance and acid-base corrosion resistance, stable long-term performance.The hardness changes little at different temperatures, and the adaptable temperature range is -30℃-100℃, which ensures the sealing performance of the sealing strip in different temperature environments.

The chemical stability of PP is very good. In addition to being corroded by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. It has good acid and alkali corrosion resistance, as well as good anti-aging and weather resistance characteristics.

TPE is one of the soft materials. TPE material is a non-toxic and environmentally friendly elastomer material, which is soft to the touch, high strength, high resilience and temperature resistance. It can reach the hygienic environmental protection standard.

Good aging resistance and acid-base corrosion resistance, stable long-term performance.The hardness changes little at different temperatures, and the adaptable temperature range is -30℃-100℃, which ensures the sealing performance of the sealing strip in different temperature environments.